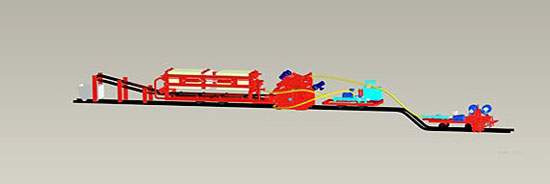

For water position clear dig the problems, Xuzhou Tianke launch process and its equipment for mine water storage dredging. After nearly a decade of technical exploration, and more than two hundred sets of dredging equipment to use in the coal mine, the craft and its equipment is more sound and mature: the formation of multi-variety series products: loading machine for dry materials composite thickness combination of materials handling equipment, dredging equipment for fine materials, to better adapt to the different traits slime dredging for tailings dewatering kinds of underground water positions and coal washing plant, sewage station processing.

Coal mine clearance machine: MQC-15, MQC-15 / F

MQC-15 / F series of mine clearance machine features:

1. Continuous and efficient: the host the dual work area filter press, the formation of a continuous operation, 1.5 to 2 times the efficiency.

2. Adaptable: all kinds of water positions in a variety of performance slime using different processes and equipment, handle better.

3. Easy to move: the equipment can be made mobile Needless disassembly, replacement venue, easy to use.

4. Full hydraulic control: many implementing agencies (belt drive roller, mixing pumps) hydraulic components, control integration, energy saving, reducing equipment investment, space-saving.

5. Special delivery pump: a filter large particles (0 ~ 11mm), Suct.lift (7.5m), a high concentration (40 to 60%).

6. Multi-species: general type, mobile, composite, directly, can be used alone or may be combined using

The series of mine clearance machine slime kinds of coal mine water positions and various traits can be achieved pumping, concentration, dewatering, loading automation and streamlined operations, and can also be used for the dewatering of the coal washery slime recovery. The equipment successfully applied in the mine of Shenhua Group, Yanzhou Mining Group, Zaozhuang Mining Group, Xinwen Mining Group, Jincheng Mining Group, Lu'an Mining Group, more than one hundred and ten positions in the clean-up of the mine water to enter the new era of mechanization cleanup.

MQC-15 / F mine clearance machine main parameters:

| No. | Device Name | Parameter name | Parameter values | |

| (1) | Dual work area filter press | MYSZ | ||

| 1 | Handling capacity (dry material) (t / h) | 3-5 | 5-8 | |

| 2 | Feeding concentration (%) | 40-50 | ||

| 3 | The material moisture (%) | ≤30 | ||

| 4 | Motor power (kw) | 11+3 | ||

| 5 | Recycled material particles (mm) | 0.02-11 | ||

| 6 | Equipment Dimensions (mm) | 5860*1450*1560 | 6550*1550*1660 | |

| (2) | Slime crude ext. | MC-1 | ||

| 1 | Total power (kw) | 2.2+4 | ||

| 2 | Production capacity (T) | 10 | ||

| 3 | Buffer volume (m 3 ) | 2.5 | ||

| (3) | Mining slurry pump | NB15/1.2-15 | ||

| 1 | Flow (m 3 / h) | 8-13 | 12-18 | |

| 2 | Head (m) | 0-120 | 1-120 | |

| 3 | Motor power (kw) | 11 | 15 | |

| 4 | Import Size (mm) | 100 | 100 | |

| 5 | Export Size (mm) | 100 | 100 | |

| (4) | Mining slurry pump | NB15/1.2-15 | ||

| 1 | Flow (m 3 / h) | 8-13 | 12-18 | |

| 2 | Head (m) | 0-60 | 0-60 | |

| 3 | Motor power (kw) | 7.5 | 11 | |

| 4 | Import Size (mm) | 100 | 100 | |

| 5 | Export Size (mm) | 100 | 100 | |

| (5) | Truck mixer (optional) | MQ-2 | ||

| 1 | Roller diameter (mm) | 500 | ||

| 2 | Drum Length (mm) | 1800-2600 | ||

| 3 | Power (kw) | 4 | ||

| 4 | Walking speed (m / min) | 10 | ||

| (6) | The agitator (optional) | RJ-3 | ||

| Power (kw) | 3 | |||

| Speed (r / min) | 1450 | |||